Schut Systems bv/PilloPak BV’s packaging prevents breakage of baker's confections

By investing in new packaging techniques, less packaging material is required and breakage of the confectionery is prevented.

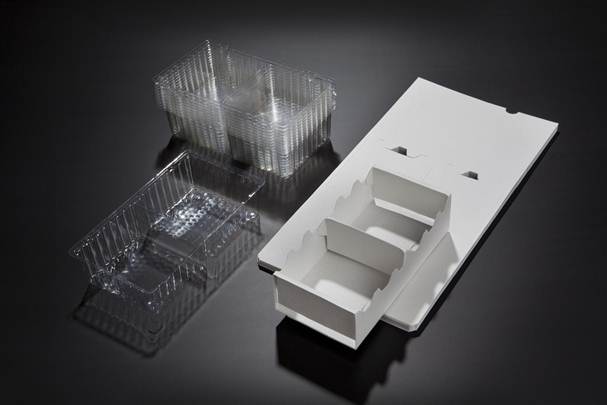

Schut Systems bv/PilloPak BV appear to have decided that, if an industrial bakery is capable of producing delicious treats, it can also develop trays from ultra-light corrugated paper itself. Corrugated paper is an alternative to plastic trays, which take up more space during transportation and need to be unstacked before use. The supplier of the packaging machines worked in collaboration with the bakery. The supplier of the corrugated paper was also involved in the development, which took two years. The fragility of the corrugated paper and technical limitations of the packaging machine made it a challenging development.

Schut Systems bv/PilloPak BV appear to have decided that, if an industrial bakery is capable of producing delicious treats, it can also develop trays from ultra-light corrugated paper itself. Corrugated paper is an alternative to plastic trays, which take up more space during transportation and need to be unstacked before use. The supplier of the packaging machines worked in collaboration with the bakery. The supplier of the corrugated paper was also involved in the development, which took two years. The fragility of the corrugated paper and technical limitations of the packaging machine made it a challenging development.

The bakery purchased a special tray-assembling machine. Unassembled trays that are supplied flat, are now assembled into trays with compartments. The ingenious assembly process is reminiscent of origami, the Japanese art of paper folding. This locking system eliminates the need for adhesive. The volume of packaging material and the associated number of transport movements have decreased. In addition, the compartments prevent breakage, which remains the most important consideration, because damaged confectionery does not sell. It is destined for the waste incineration plant. All the energy that was invested in the raw materials and in the production of the treats is gone. Since packaging requires less energy, that would be the biggest waste of all.